EV Basics L1 A

Basic Components of Electric Vehicles

Overview

Electric vehicles (EVs) represent a fundamental shift from internal combustion engines to electric propulsion systems. Understanding the key components and their interactions is essential for automotive engineers. This guide covers the ten primary systems that make EVs function effectively.

graph TD

A[Battery] --> B[Motor]

B --> C[Wheels]

A --> D[12V Systems]

E[Charger] --> A

F[Control Unit] --> A

F --> B1. Battery Pack

Function: Primary energy storage system that powers the entire vehicle

Key Points

- Most EVs use lithium-ion battery technology due to high energy density

- Typically operates at 400V or 800V nominal voltage

- Measured in kilowatt-hours (kWh) - determines driving range

- Battery chemistry affects performance: NMC (Nickel Manganese Cobalt) for performance, LFP (Lithium Iron Phosphate) for cost-effectiveness

Engineering Considerations

- Energy density vs. power density trade-offs

- Cycle life (typically 1000-3000 charge cycles)

- Temperature sensitivity affects performance and lifespan

graph TD

A[Battery Pack] --> B[High Energy Density]

A --> C[High Voltage 400-800V]

A --> D[Capacity kWh]

B --> E[Lithium-ion Technology]

E --> F[NMC Chemistry]

E --> G[LFP Chemistry]

F --> H[High Performance]

G --> I[Cost Effective]2. Battery Management System (BMS)

Function: Electronic "brain" that monitors and controls battery operation

Key Responsibilities

- Cell monitoring: Tracks voltage, current, and temperature of individual cells

- State estimation: Calculates State of Charge (SOC) and State of Health (SOH)

- Protection: Prevents overcharging, over-discharging, and thermal runaway

- Cell balancing: Ensures all cells charge/discharge evenly

Why It's Critical

Without proper BMS control, lithium-ion batteries can become dangerous or degrade rapidly. The BMS acts as a safety net and performance optimizer.

graph TD

A[BMS] --> B[Monitor Cells]

A --> C[Calculate SOC]

A --> D[Balance Cells]

A --> E[Safety Protection]3. Motor Controller

Function: Electronic control unit that regulates electric motor operation

How It Works

- Receives commands from vehicle control unit (accelerator pedal position, desired torque)

- Controls motor speed and torque through precise electrical switching

- Implements control algorithms (typically Field Oriented Control for AC motors)

- Provides regenerative braking functionality

Key Features

- High-frequency switching (typically 10-20 kHz)

- Real-time feedback control using motor position sensors

- Safety interlocks and fault detection

graph TD

A[Driver Input] --> B[Motor Controller]

B --> C[Motor]

C --> D[Feedback]

D --> B4. Electric Motor

Function: Converts electrical energy into mechanical motion to propel the vehicle

Common Types

- Permanent Magnet Synchronous Motor (PMSM): High efficiency, compact, uses rare earth magnets

- Induction Motor: Robust, no rare earth materials, slightly lower efficiency

- Switched Reluctance Motor: Simple construction, lower cost, higher noise

Key Characteristics

- High torque at zero RPM (instant torque delivery)

- Efficiency typically 90-95%

- Can operate as generator during regenerative braking

- Much simpler than internal combustion engines (few moving parts)

graph TD

A[Motor Types] --> B[PMSM

95% Efficient]

A --> C[Induction

90% Efficient]

A --> D[Switched Reluctance

Low Cost]5. EV Transmission

Function: Transfers power from motor to wheels, often with gear reduction

Types

- Single-speed reduction: Most common, typically 8:1 to 12:1 gear ratio

- Multi-speed: Some performance EVs use 2-speed for efficiency optimization

- Direct drive: Some designs eliminate transmission entirely

Why Different from ICE

Electric motors have wide speed ranges and don't need multiple gears like internal combustion engines. Most EVs use simple single-speed reductions.

block-beta

columns 3

A["Transmission Type"]:3

B["Single-Speed"]:1

C["Multi-Speed"]:1

D["Direct Drive"]:1

F["Gear Ratio"]:3

G["8:1 to 12:1"]:1

H["2-Speed Typical"]:1

I["No Gears"]:1

K["Usage"]:3

L["Most Common"]:1

M["Performance EVs"]:1

N["Maximum Simplicity"]:1

P["Key Features"]:3

Q["Simple & Reliable"]:1

R["Efficiency Optimization"]:1

S["Motor Direct to Wheels"]:1

style A fill:#409f00,color:#fff

style F fill:#0a9ff7,color:#fff

style K fill:#0f00e2,color:#fff

style P fill:#00f0e2,color:#fff6. Onboard & Offboard Chargers

Onboard Charger

Function: Converts AC power from electrical grid to DC power for battery charging

Specifications:

- Typical power levels: 3.3kW, 6.6kW, 11kW, 22kW

- Includes Power Factor Correction (PFC) for grid compatibility

- Built into the vehicle

Offboard Charger (DC Fast Charging)

Function: External high-power DC charging systems

Specifications:

- Power levels: 50kW to 350kW+

- Bypasses onboard charger, charges battery directly

- Enables rapid charging (20-80% in 15-45 minutes)

graph TD

A[AC Grid] --> B[Onboard Charger

3-22kW]

B --> C[Battery]

D[DC Fast Charger

50-350kW] --> C7. Inverter

Function: Converts DC power from battery to AC power for motor operation

Technical Details

- Uses power electronics (IGBTs or MOSFETs) for switching

- Creates three-phase AC waveforms from DC input

- Operates bidirectionally (motor mode and generator mode)

- Includes filtering to reduce electromagnetic interference

Integration

Often integrated with motor controller in a single unit called a "motor control unit" or "power electronics unit."

graph LR

A[DC Battery] --> B[Inverter]

B --> C[AC Motor]

C --> B

B --> A8. DC-DC Voltage Converter

Function: Steps down high-voltage battery power to 12V for auxiliary systems

Why Needed

- Main battery operates at 400V or 800V

- Traditional automotive electronics (lights, radio, ECUs) operate at 12V

- Replaces the alternator found in conventional vehicles

Types

- Unidirectional: Battery to 12V system only

- Bidirectional: Can also charge main battery from 12V system (useful during vehicle startup)

graph TD

A[High Voltage

400-800V] --> B[DC-DC

Converter]

B --> C[12V Systems

Lights, Radio, ECUs]9. Thermal Management System

Function: Controls temperature of critical EV components

Components Managed

- Battery cooling: Liquid cooling loops or air cooling to maintain 15-35°C

- Motor/inverter cooling: Prevents overheating during high-power operation

- Cabin heating/cooling: Heat pump systems for efficiency

System Types

- Air cooling: Simple, lower cost, limited effectiveness

- Liquid cooling: More effective, uses coolant loops with radiators

- Refrigerant cooling: Most advanced, can provide heating and cooling

Importance

Temperature directly affects battery life, motor efficiency, and component reliability. Poor thermal management can reduce range and component lifespan significantly.

graph TD

A[Thermal System] --> B[Battery Cooling

15-35°C]

A --> C[Motor Cooling]

A --> D[Cabin Climate]10. Vehicle Control Unit (VCU) and Control Electronics

Function: Central "brain" that coordinates all vehicle systems

Key Responsibilities

- Torque management: Interprets driver inputs and commands motor controller

- Energy management: Optimizes power flow between components

- Safety systems: Monitors system health and implements safety protocols

- Communication: Coordinates between all electronic control units (ECUs)

Additional Control Electronics

- Gateway modules: Handle communication between different vehicle networks

- Body control modules: Manage lights, doors, HVAC

- Telematics units: Enable connectivity and over-the-air updates

graph TD

A[Vehicle Control Unit] --> B[Torque Control]

A --> C[Energy Management]

A --> D[Safety Systems]

A --> E[Communication]System Integration

Understanding how these components work together is crucial:

sequenceDiagram

participant Driver

participant VCU

participant MC as Motor Controller

participant INV as Inverter

participant Motor

participant BMS

participant Battery

Driver->>VCU: Accelerator Input

VCU->>MC: Torque Command

MC->>INV: PWM Control Signals

INV->>Motor: 3-Phase AC Power

Motor->>VCU: Speed/Position Feedback

BMS->>Battery: Monitor Cells

Battery->>INV: DC Power Supply

BMS->>VCU: Battery Status

VCU->>BMS: Power Limits

Power Flow Diagram

graph LR

A[Battery] --> B[Power Delivery System] --> C[Motor]--> D[Transmission] --> E[Wheels]

A --> F[12V Systems]

E[Charging] --> AKey Advantages of EV Architecture

Efficiency Comparison

pie title ICE Energy Efficiency

"IC Engine Loss" : 50

"Energy to Wheel" : 35

"Transmission & Other Losses" : 15pie title EV Energy Efficiency

"EV Motor Loss" : 5

"Energy to Wheel" : 80

"Transmission & Other Losses" : 15System Benefits

- Efficiency: Electric drivetrain is 3-4x more efficient than ICE

- Simplicity: Fewer moving parts than conventional vehicles

- Controllability: Precise electronic control of all systems

- Integration potential: Systems can be optimized together

- Scalability: Components can be sized for different vehicle classes

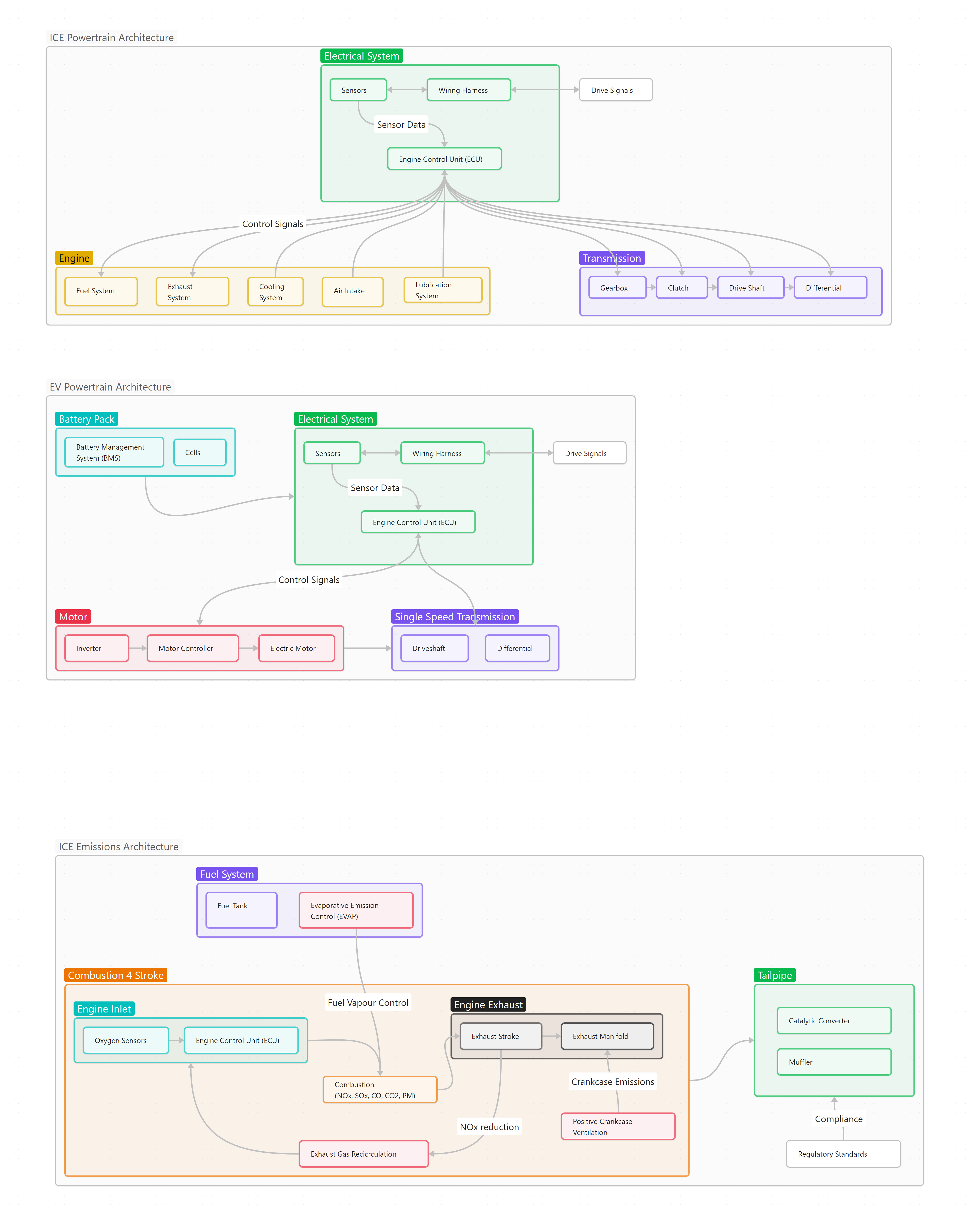

System Boundaries

Difference Between ICE (Internal Combustion Engine) and EV (Electric Vehicle):

| Feature | ICE | EV |

|---|---|---|

| Energy Source | Fuel (Petrol/Diesel) | Battery (Electricity) |

| Efficiency | ~25-30% | ~80-90% |

| Emissions | High (CO₂, NOx) | Zero tailpipe emissions |

| Maintenance | High (engine, oil changes) | Low (fewer moving parts) |

| Noise | Loud | Silent operation |

| Performance | Gradual acceleration | Instant torque and acceleration |

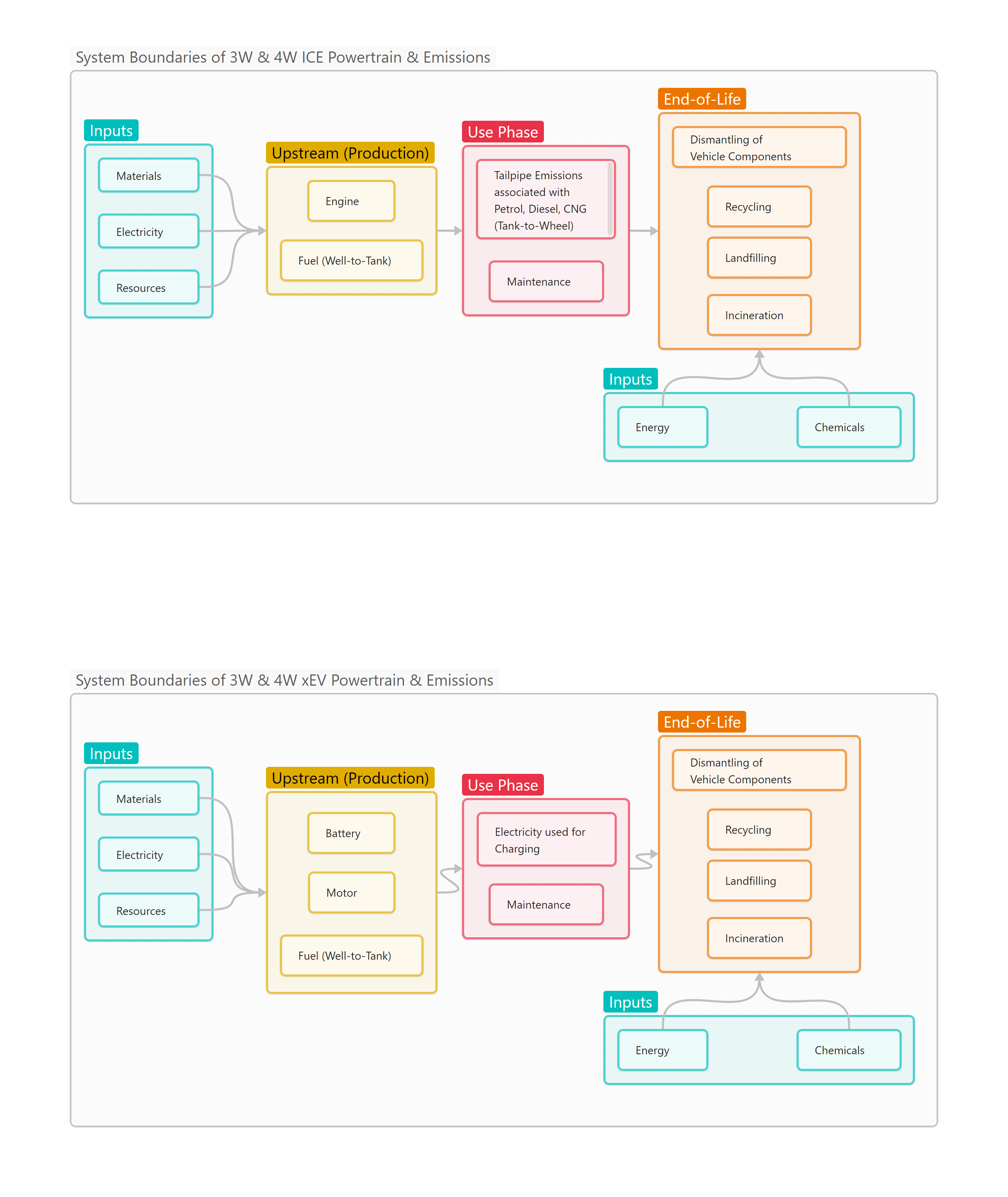

Life Cycle Analysis (LCA)

- xEVs generally tend to have higher environmental costs associated at production and end-of-life phases

- ICE on the other hand has higher use phase emissions due to its reliance on fossil fuel for propulsion and the emissions the tailpipe will generate

- As use phase for average vehicles is pretty long at 15 years/ 1,00,000 (1L)kms, the total GHG emissions of ICE are higher when compared to other xEVs

Scan the QR Code or Click on the link to view an LCA calculator